🚨 Common Safe Problems Caused by Poor Maintenance & Misuse

Safes are built to be strong, reliable, and long-lasting—but like any precision device, they need proper care to keep functioning smoothly. At Crono Lock, we often get called to open or repair safes that shouldn’t have failed… and most of the time, it’s not the safe’s fault—it’s neglect or rough handling.

Whether you’re running a business, managing staff, or just using a home safe, here are some of the most common problems we see that are totally preventable.

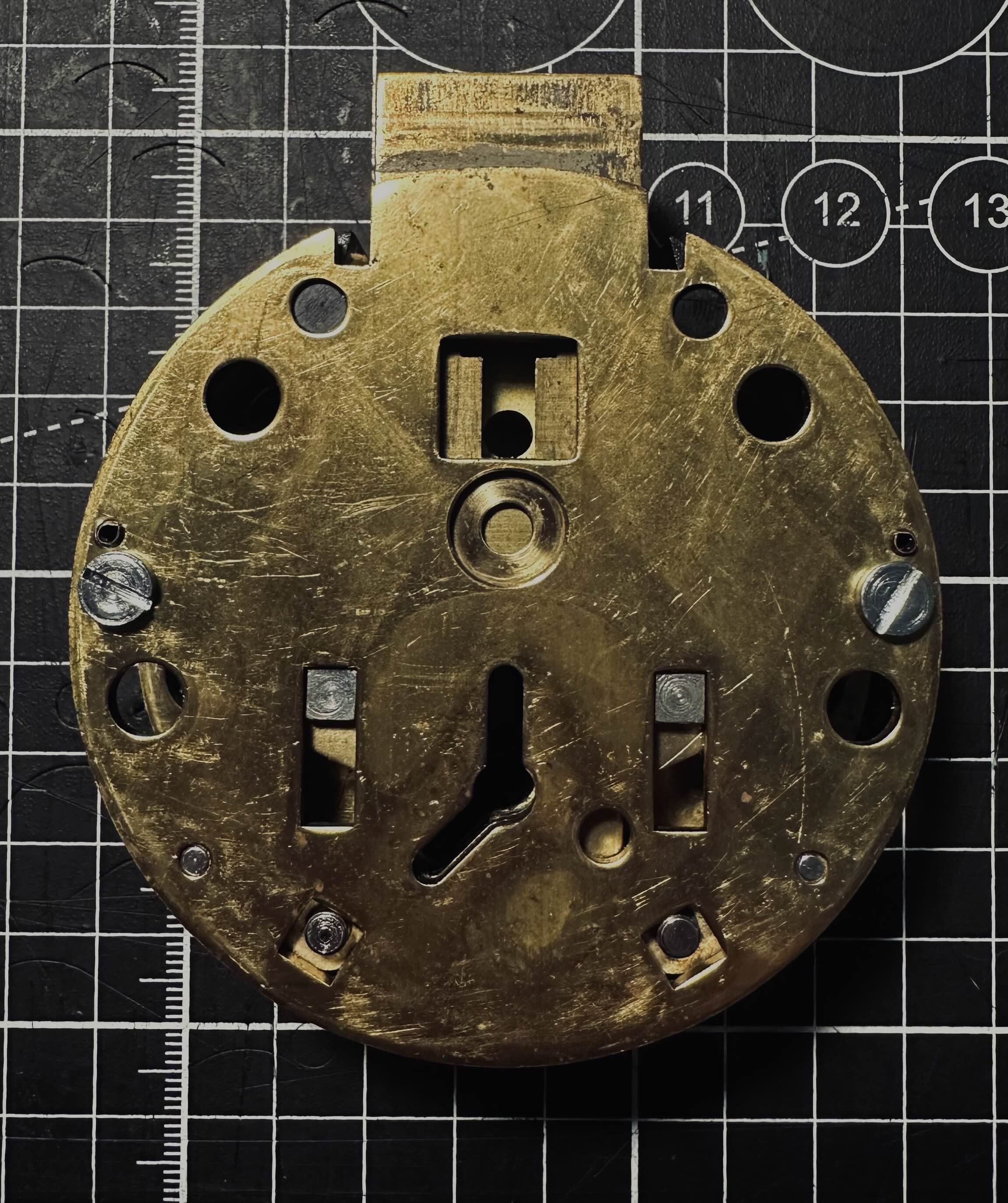

1. 🧼 Dirty or Gummed-Up Wheel Packs

Inside a mechanical safe lock is a set of precision components called a wheel pack. These parts are responsible for aligning your combination correctly so the safe can open.

Over time, dust, debris, and even humidity can cause the lubricant inside to gum up. This can lead to:

Sluggish or stiff dial movement

Incorrect gate alignment

Failure to unlock even with the correct combo

🛠️ Tip: Schedule a service every few years. A safe technician can clean and lubricate the lock without compromising the mechanism.

2. 📉 Dropping the Safe Head (or the Whole Safe)

This one happens more often than you'd think—especially in businesses where the safe gets moved or the safe door/head gets removed for service and someone drops it. Safes are heavy, and even a short drop can:

Knock the lock out of alignment

Damage internal boltwork

Crack mounting points or wiring (in electronic safes)

🛠️ Tip: Always move safes with care. If staff are handling a safe head or door, make sure they're trained or supervised by someone who knows how to handle the weight.

3. 🔩 Loose or Misaligned Bolts

Safe bolts are what physically secure the door in place, and over time, bolts can become loose or out of sync—especially on safes that are slammed shut frequently or not aligned properly when closed.

This can lead to:

Difficulty turning the handle or dial

Doors that won’t lock or unlock smoothly

Bolt binding, which can completely jam the safe

🛠️ Tip: Avoid slamming the safe shut, and teach staff to make sure the door is fully seated before locking. If the handle starts to feel “off,” get it checked before it escalates.

4. 🔋 Neglecting Battery Changes (Electronic Locks)

Many modern safes use an electronic keypad. These are convenient, but if the batteries die or leak, you can be locked out. Worse, a low battery might give a false sense of security by turning on but failing during a code entry.

🛠️ Tip: Change batteries once a year (use name-brand), and avoid cheap dollar-store brands that are prone to leaking.

5. ❌ Forcing the Handle or Dial

If a safe doesn’t open right away, some users panic and apply force—bending the handle or stripping internal gears in the process. Safe mechanisms are precise. Forcing them will only make the problem worse.

🛠️ Tip: If your safe isn’t opening and you’re sure the combo or code is correct, stop. Don’t force it. Call a technician before you cause permanent damage.

6. 🗝️ Reusing or Guessing Old Combinations

Believe it or not, many combination lockouts come down to people:

Guessing old combinations

Misremembering the dial sequence

Writing down codes incorrectly

Or worse—staff members trying to open the safe without training.

🛠️ Tip: Train your team properly on how to open and close the safe. Keep records secure and rotate combinations regularly.

Final Thoughts

Safes are built to last—but only if you treat them right. Just like a car, they need occasional maintenance and respectful handling. At Crono Lock, we’ve seen it all—from safes jammed with paperclips to boltwork wrecked by brute force.

If your safe is acting up or due for a check-up, give us a call. A simple service visit now can prevent an expensive lockout—or worse—a failed safe when you need it most.